If you are using standalone ECU or your car doesn’t send torque over CAN you need a way of telling TCU how much NMs your engine is generating

Make sure that you installed MAP sensor or you are using MAP over CAN (MAP input: 13)

- Open “Torque Calculation”

- Enable flag “Automatic detection of torque calculation input”

- Set “Torque Calculation Input” to 0

- Select one map “Base Torque Table RMP/MAP” which uses your desired units of torque

- This map must be adjusted to reflect torque your engine is generating at given manifold pressure. Any problems with rough shifting should start by checking if that table is correct

- Base map is good start point that needs to be adjusted to your engine

Adjusting the map #

- Start by multiplying whole map to bring it to your engines TQ numbers.

- Calculate how much you need to multiply base map.

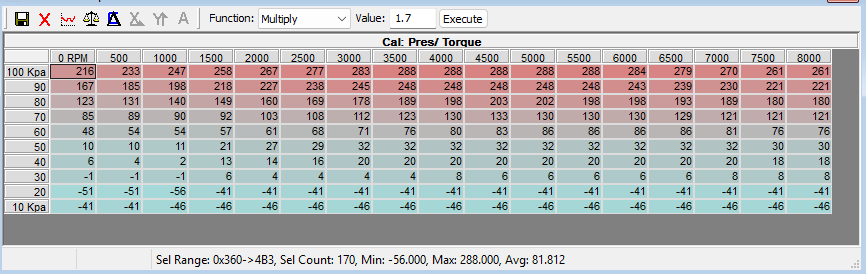

- Example for N\A M73B54 which has peak TQ of 490NMs. Pick peak NMs on the map which in base map is 288. 490/288=1.7 (remember that this map is max 100kPa or atmospheric pressure, for turbo cars there is another map “Pressure\Torque Multiplier” for boost but it shouldn’t be modified in most cases)

- Select all cells in the map, select Function Multiply and set value to what you calculated and press Execute (example below)

- Save and upload it to the TCU

- Calculate how much you need to multiply base map.

- Turn on your engine and check current Engine TQ (CAN Tq dashboard) it should be between 10-20 NMs. It’s useful to turn on Data Tracing in TunerPro. You will be able to see on the map where exactly you are.

- If you have more/less than 10-20NMs. Adjust it slightly will all the cells around it to bring it to correct value. This might need bigger adjustments with big cams or rotary engines

- Rev your engine to around 3000RPM and hold it there. With RPMs not moving make sure again that your torque is around 10-20 NMs. Do the same at 5000 RPM

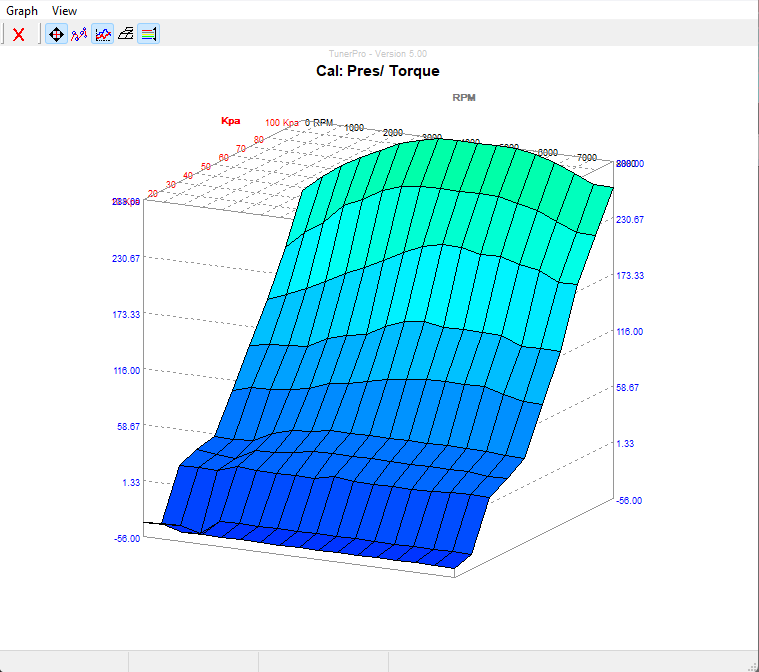

- Press “Show Table Graph (3rd icon from left) and make sure that map looks smooth in 3d, if not adjust it

- Test drive the car slowly and make sure that gear changes are smooth and clutches are not being slipped extensively